Leading the Charge in New Space Manufacturing

Spacecraft technology is experiencing a revolution in manufacturing. The epoch of hand-built satellites is over. Constellation operators are building multiple satellites daily on assembly lines. Launchers are placing hundreds of serialized spacecraft in orbit. The satellite component supply chain must be re-invented to keep up with this new demand. Production capacity must increase, costs must be reduced, but reliability must remain supreme. Orbion is leading this charge.

Quality Management & Supplier Standards (AS9100D Certified)

Orbion’s Quality Management System is certified to the AS9100D standard — the aerospace industry’s benchmark for disciplined processes, traceability, and reliability. This certification covers “the design, manufacture, qualification, sale, and support of satellite propulsion systems” (Registrar: NSF-ISR).

Our commitment doesn’t stop at our own processes. We believe the best results come from strong, mutually beneficial partnerships. To support that, Orbion maintains a Supplier Quality Manual that clearly communicates requirements, responsibilities, and expectations for all suppliers and outsourced partners. Every supplier is accountable for the quality of their materials, parts, and services — including flowing down applicable requirements to their own third-party sources.

Download Supplier Quality ManualThrusters Built by Thruster Experts

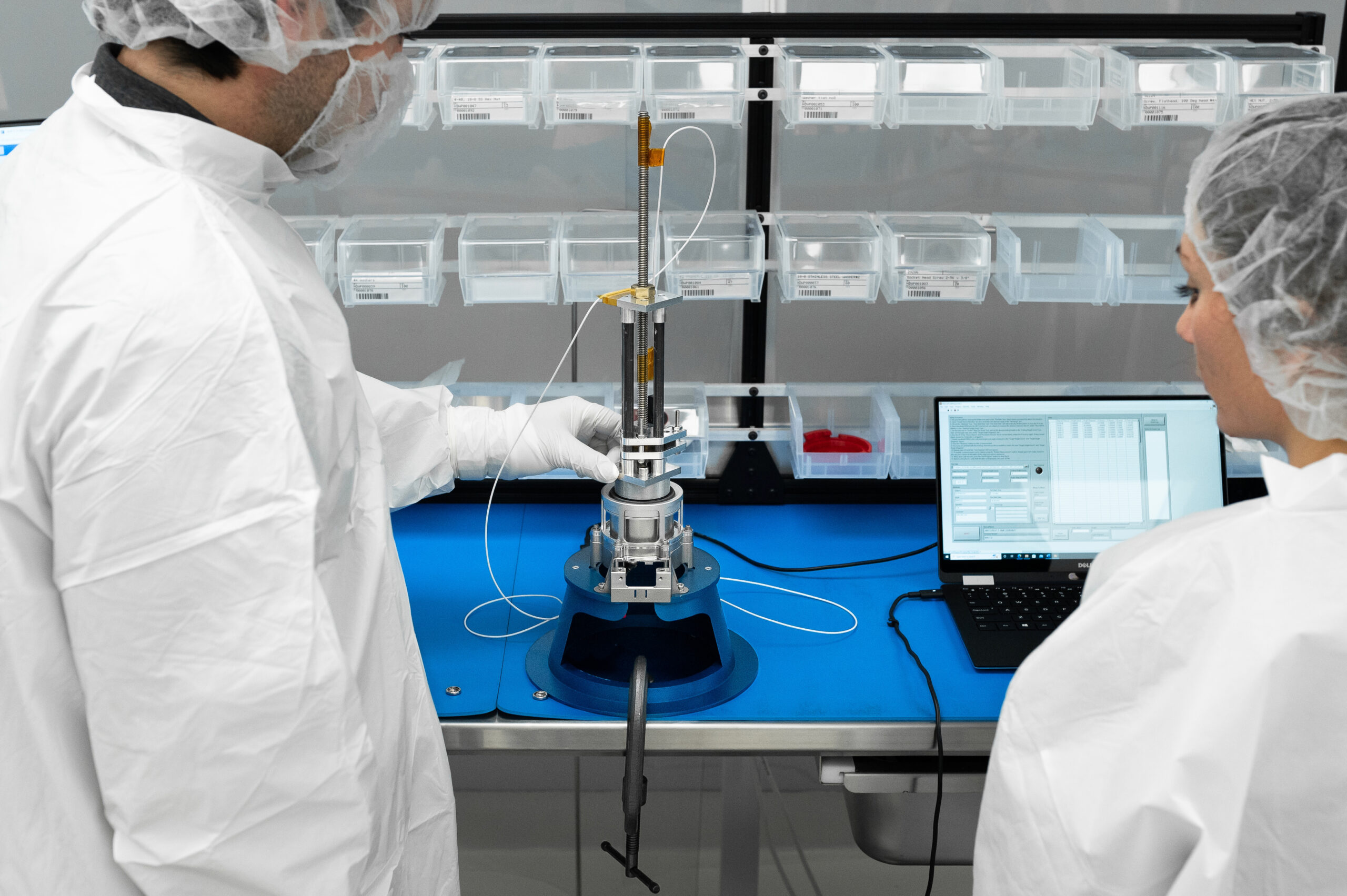

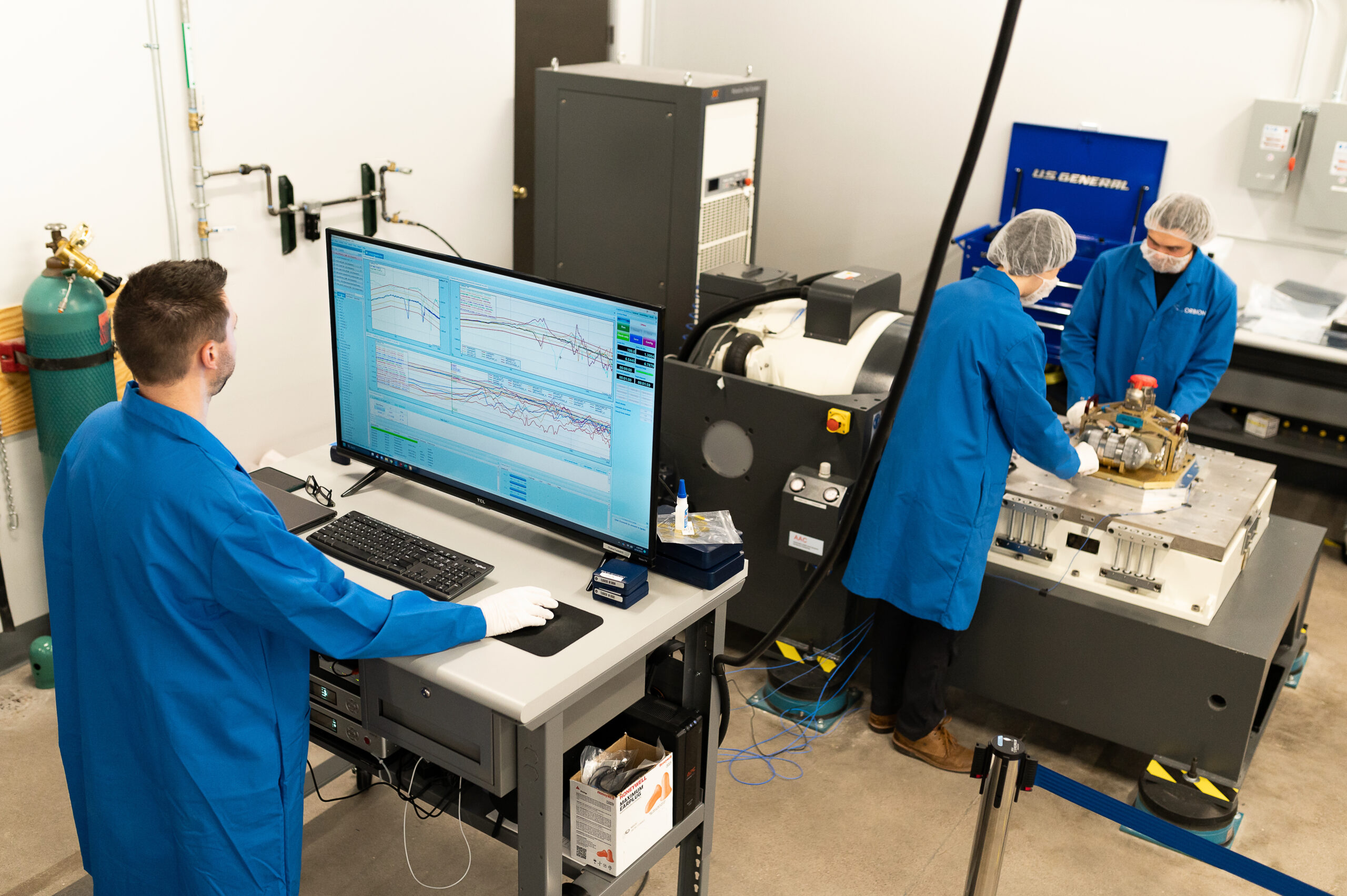

Manufacturing is more than just putting parts together. Each Orbion unit is assembled, inspected, and tested under our roofline by the expert team that designed it. Orbion’s in-house manufacturing safeguards the quality of the product through the entire lifecycle and reduces supply chain dependency on third parties.

Rigorous Acceptance Testing

At Orbion, we believe anything less than full acceptance testing of each unit is a risk customers should not have to carry. Quality assurance and quality control are of utmost importance to us. Period. When you receive your Orbion products, you can rest assured each serial number was subjected to rigorous component- and system-level acceptance testing, including:

Acceptance testing of each and every unit we manufacture includes:

- Electrical functional tests

- Electronic burn-in

- Dimensional & visual inspection

- Flow & leak tests

- Vibration testing

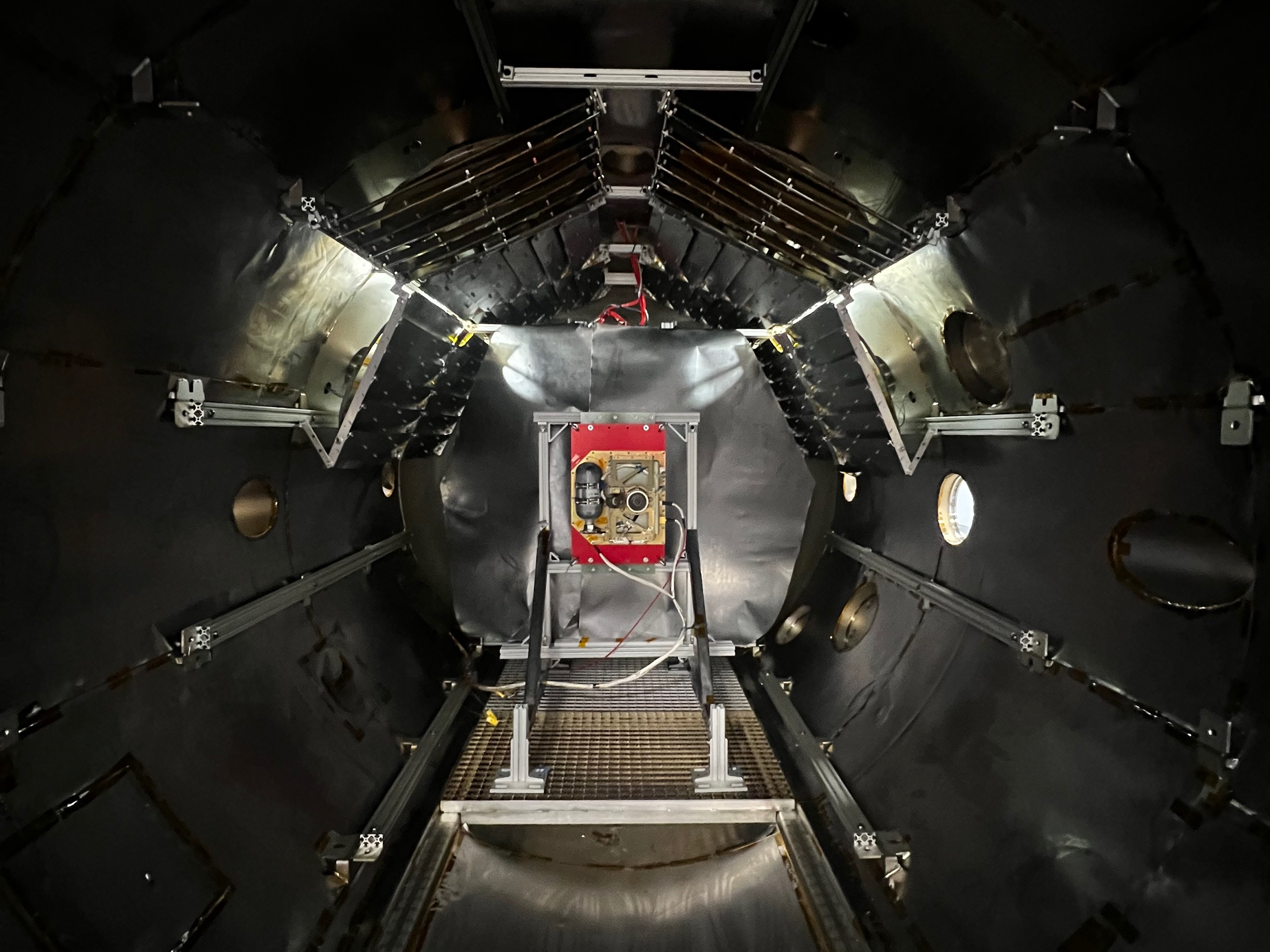

- Thermal-vacuum cycling

- In-vacuum performance testing across full throttle range

- Exhaust plume diagnostics

Meet the Orbion Team

Orbion’s engineers have built 100s of space hardware components that are flying all over the solar system

Orbion’s ExpertiseThruster configurator

Design a propulsion system that meets your mission requirements and download custom slides.

Configure your systemGet in touch

Partner with us as we redefine what’s possible using small satellite technology

Contact us